Abrasion and Wear Protection

Impact, Wear & Abrasion Solution products marketed globally, help to optimize process performance while achieving the targets of customers. The products are tailored to suit the customer specific needs and expectations.

Rubber is an excellent material for use against high wear and tear areas of mineral processing in grinding mills and material handling equipments like transfer chutes. Decades of field experience have established wear products of T300, T800, TWAR with THOR, RHINO, CERALINE, WARDOG etc. liners and sheets as one of the best wear solutions in the mining and mineral processing industry.

Wear solutions offering in:

- Rubber

- Composite Liners (Rubber & Alloy Steel), (Rubber & Ceramics), (PU&Ceramics)

- Ceramic

- Polyurethane

- UHMWPE etc.

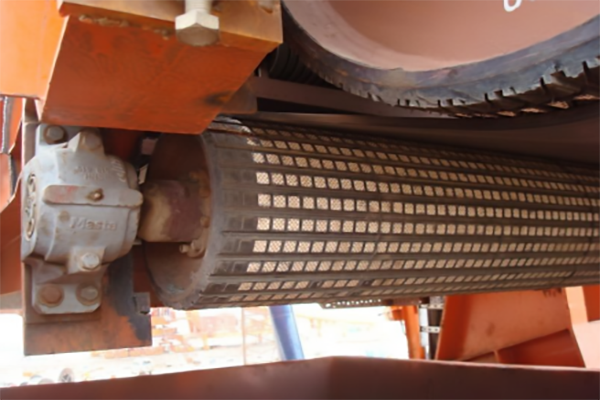

Ceramic Sheet

ERALAG sheets are ceramic tile embedded lagging sheets used for extreme application subjected to, wet/slurry conditions, high speeds, high tonnage, long distance and inclined conveyors.

Rubber Sheet

WARDOG sheeting are manufactured from highest grade of Natural Rubber. It is specifically designed to deliver superior properties of resilience, strength, cut & tear resistance with wet abrasion resistance of the highest standards.

Mill Liners

THOR – R mill liners are manufactured from specially formulated rubber compounds, which are blends of Natural and Synthetic rubbers. The T800 rubber formulation series have proved its robustness over time, through installations across a wide range of minerals and sizes of mills.

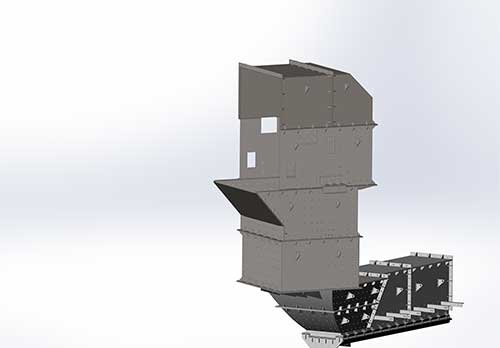

Conveyor Chute Liners

Rhino Bulk Flow Chutes are designed with advanced 3D modelling software and then simulated with Advanced Discrete Element Method Modelling (ADEM) with respect to the actual duty conditions.

Rubber Lined Pipes

We fabricate pipes and fittings suitable for slurry handling applications. While the internals of the same are protected with WARDOG grades of rubber sheetings to resist wet abrasion, external are applied protective coatings

Pressure and Vaccum Hoses

Thejo offers, acid-alkali and non abrasive special fabric and wire reinforced rubber hoses suitable for Pressurised or Vacuum services.

Twister Cyclone & Pump Spares

We fabricate hydro cyclone as per customer requirement and supply with either hot bonded rubber or with drop in moulded liners. Wear parts are available in rubber and polyurethane.

About us